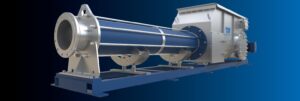

Pump with unique availability

The influence of liquid pumps on the safety and availability of materials processing units is often underestimated. For the handling of toxic, abrasive and aggressive media, the utilization of such pumps is recommendable whereby the fluid is not in contact with sliding seals. The FELUWA hose diaphragm piston pump is a hermetically sealed, leak-proof, reciprocating positive displacement pump with unique technical and economical value.

It efficiently and reliably transports slurries and pastes of very different consistencies be they chemically aggressive and mechanically abrasive, fluid or highly viscous.

With the FELUWA hose diaphragm piston pump, the commonly utilised principle of a flat diaphragm has been modified into a flexible hose (hose diaphragm) that is set in motion by an actuation fluid which provides the displacement of the product. The wetted operating chamber is thus hermetically sealed from the hydraulic system by means of a functionally determined partition (hose diaphragm). Unlike mechanically driven hose pumps, the hose diaphragm of the FELUWA hose diaphragm piston pump is not fully

compressed. Instead with each stroke of the piston it makes a movement comparable with a pulsating human vein so that its service life is considerably extended beyond that of a flat diaphragm. The constant displacement-controlled elastic distortion of the hose diaphragm is concentrically directed and bound by its form.

The distinct advantage of this pump design is its linear flow path, which is particularly advantageous when handling suspensions, viscous fluids or media that either include solids, are of abrasive nature or may be shear sensitive. All components are separated from the conveyed fluid. The enormous advantage of this pump design is that the conveyed fluid is in contact with the inside of the hose diaphragm and valves only, whereas with typical diaphragm piston pumps the pump chamber and pump cover are wetted by the product also. By this means, corrosion and erosion are practically avoided. Faults arising, that may otherwise impact on the mechanical integrity of this hose diaphragm are signalled by appropriate alarm devices.

If the hose diaphragm fails, the pump may continue to operate with the reliability of a traditional diaphragm piston pump until the process allows for the next scheduled shut-down of the unit.

Source: FELUWA Pumpen GmbH