Diaphragm valves made of Alloy 59

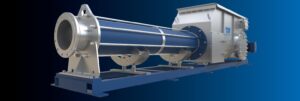

For the first time, SISTO Armaturen S.A., a company of the KSB Group, have produced diaphragm valves made of Alloy 59. This material is a special, particularly corrosion-resistant steel. More than one thousand of the pneumatically or manually actuated valves are destined for use in a pharmaceutical technology centre in the German city of Wuppertal. The centre was built by a major German pharmaceutical group for the research and development of new materials.

The positive experience gained with this valve type in similar applications tipped the scales in favour of the Luxembourg valves. Its modular design offers just what the customer wants: for example, a leakage indicator incorporated in the valve bonnet warning the operator of leaks on the primary seal.

An additional self-sealing gland packing complying with the

German clean air regulations (TA-Luft) serves as a secondary seal.

As the limit switch housings and the pneumatic actuators have the same outer diameter, they form a smooth and even surface which allows easy cleaning, i.e. "disinfection in place". Alloy 59 was chosen so as to avoid potential constraints that the piping and valve materials might have posed on future media handling.

Source: KSB SE & Co. KGaA